Why the lower rollers of Dozers and Tractors are of 2 types?

Some machines (Dozers and Tractors) simultaneously mount 2 different types of lower rollers.

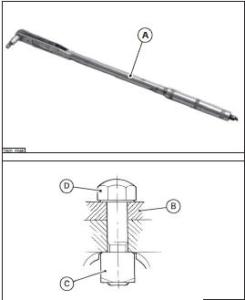

One has only 2 outer shoulders that contain the chain while another type has two other internal shoulders that form 2 guides for the links of the chain (see photo).

This makes it possible to avoid the undercarriage of the undercarriage chain (the so-called "skidding") since the chain guides are not mounted on these machines, as for example in excavators.

The fact that both types are mounted is linked to both a cost problem (the 2-edged roller costs more) and a problem of overall dimensions.

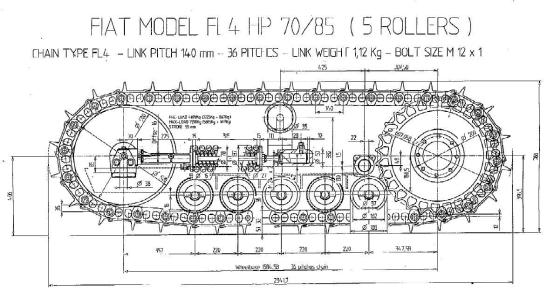

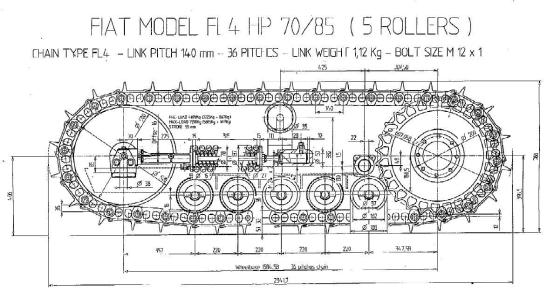

If you look at the image below you can see that the drive wheel intersects the last roller on the right and if there were any internal edges this would not be possible. The same goes for the front roller: if you want to design a more compact undercarriage (this is not the case of this FIAT undercarriage), the tensioning spring comes to intersect with the front roller and the presence of the inner edges would not allow this intersection .

One has only 2 outer shoulders that contain the chain while another type has two other internal shoulders that form 2 guides for the links of the chain (see photo).

This makes it possible to avoid the undercarriage of the undercarriage chain (the so-called "skidding") since the chain guides are not mounted on these machines, as for example in excavators.

The fact that both types are mounted is linked to both a cost problem (the 2-edged roller costs more) and a problem of overall dimensions.

If you look at the image below you can see that the drive wheel intersects the last roller on the right and if there were any internal edges this would not be possible. The same goes for the front roller: if you want to design a more compact undercarriage (this is not the case of this FIAT undercarriage), the tensioning spring comes to intersect with the front roller and the presence of the inner edges would not allow this intersection .